INJECTION MOLD MANUFACTURING

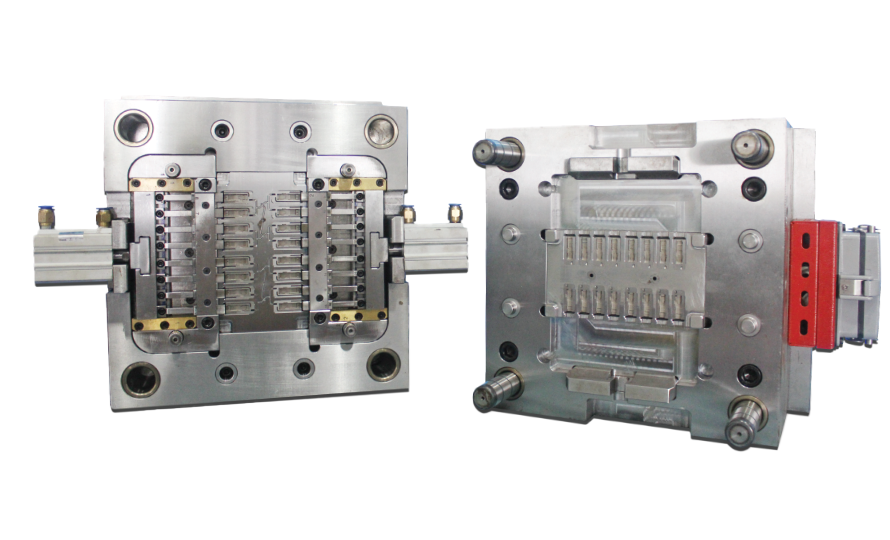

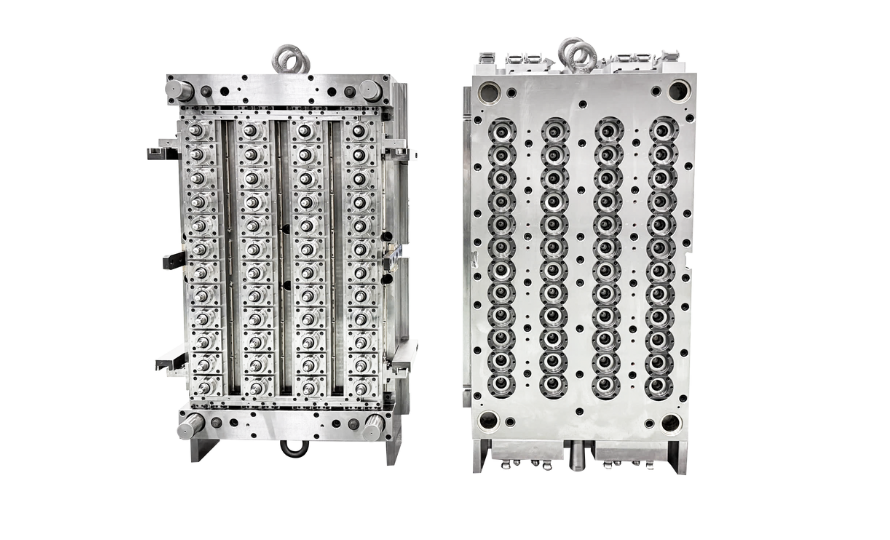

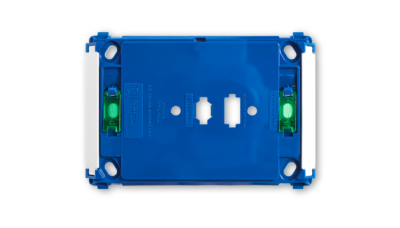

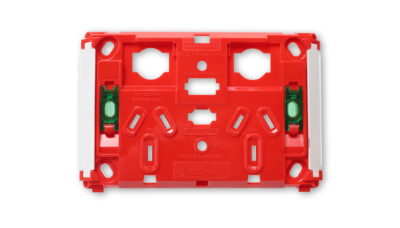

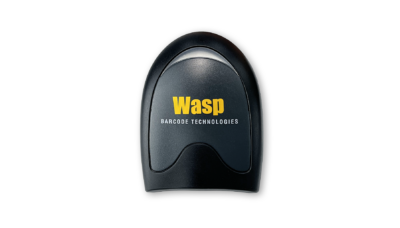

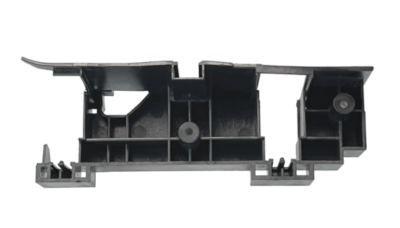

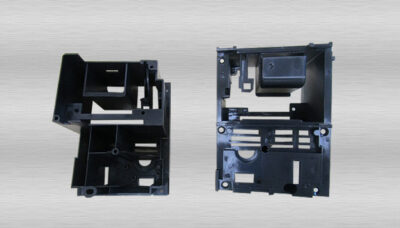

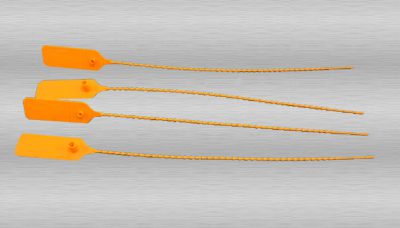

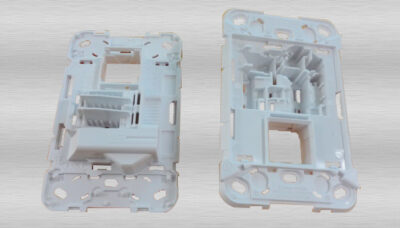

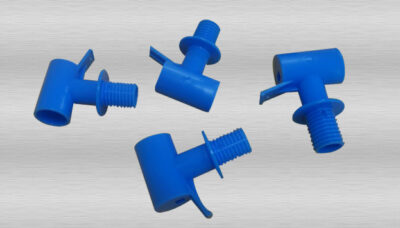

Fabricate all kind of molds:

|

|

|

|

MIDA is a professional partner in providing one-stop shop for precision mold & plastic component.

- 16 CNC, 12 EDM & Wire-Cut of Yasda, Makino,Mazak, Charmilles & other conventional machines.

- Modern measurement equipments: CMM, 3DProjector, Micro-scope, micro electric scale, …

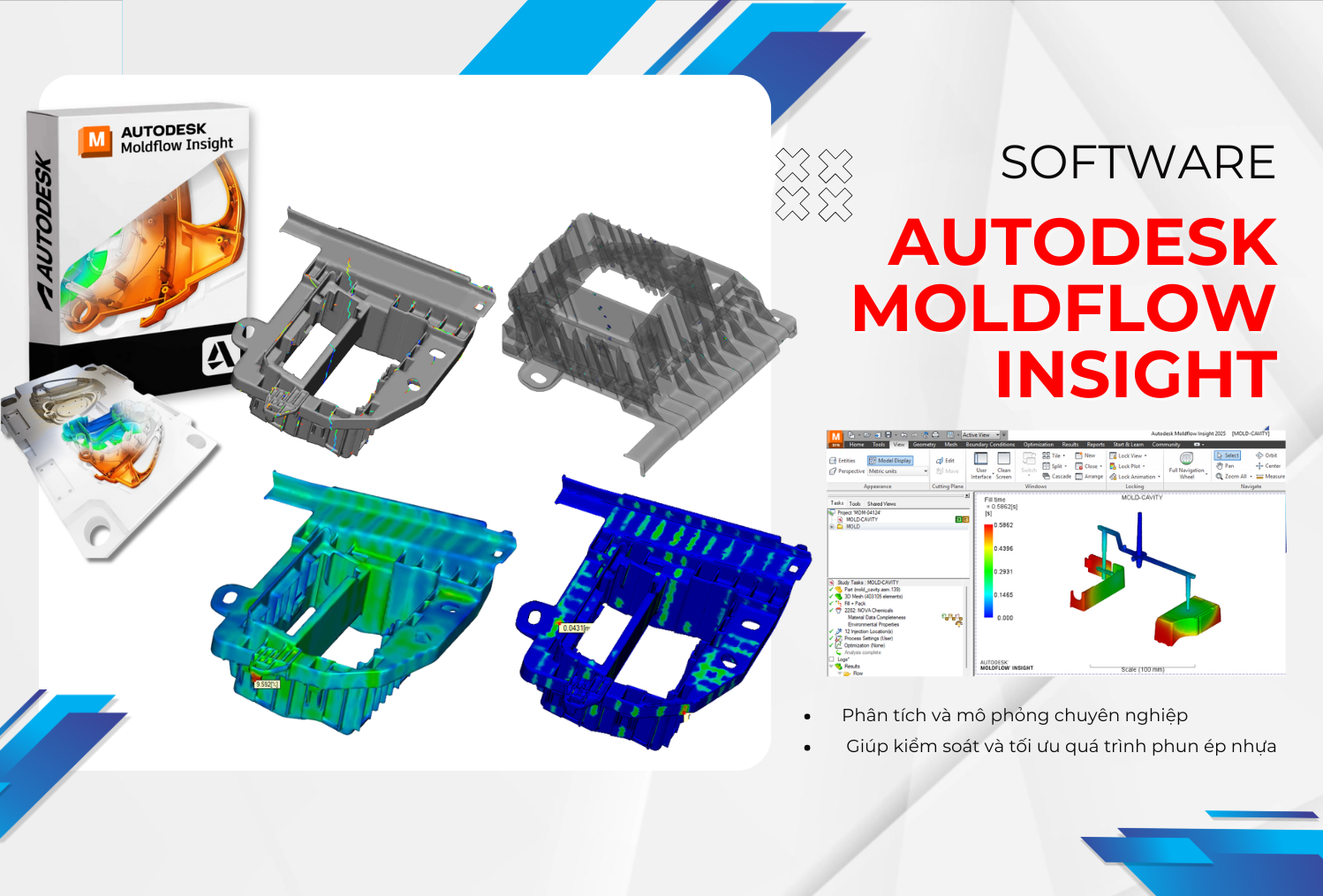

- CAD, CAM, CAE design.