Features and Specifications Multi cavity mold 02

Moldbase: Futaba, Hasco standard

Components: Misumi, Hasco standard

Material (Core, Cavity): NAK80, STAVAX, SKD11, SKD61, 2083,...

Lead time: 30-45 days

Warranty time: 300.000 shots, 1.000.000 shots

Multi cavity mold 02, using cutting-edge mold polishing technology developed in Singapore and diamond powder for polishing, we achieve a mirror-like shine. This is the highest gloss level according to international standards for durable and precise molds. It ensures smoothness during continuous plastic injection operations, where the mold needs to slide lightly and smoothly.

With a precision grinder accurate to the micron level from the Okamoto brand in Japan, it meets the requirements for smooth sliding between Multi cavity mold 02 parts

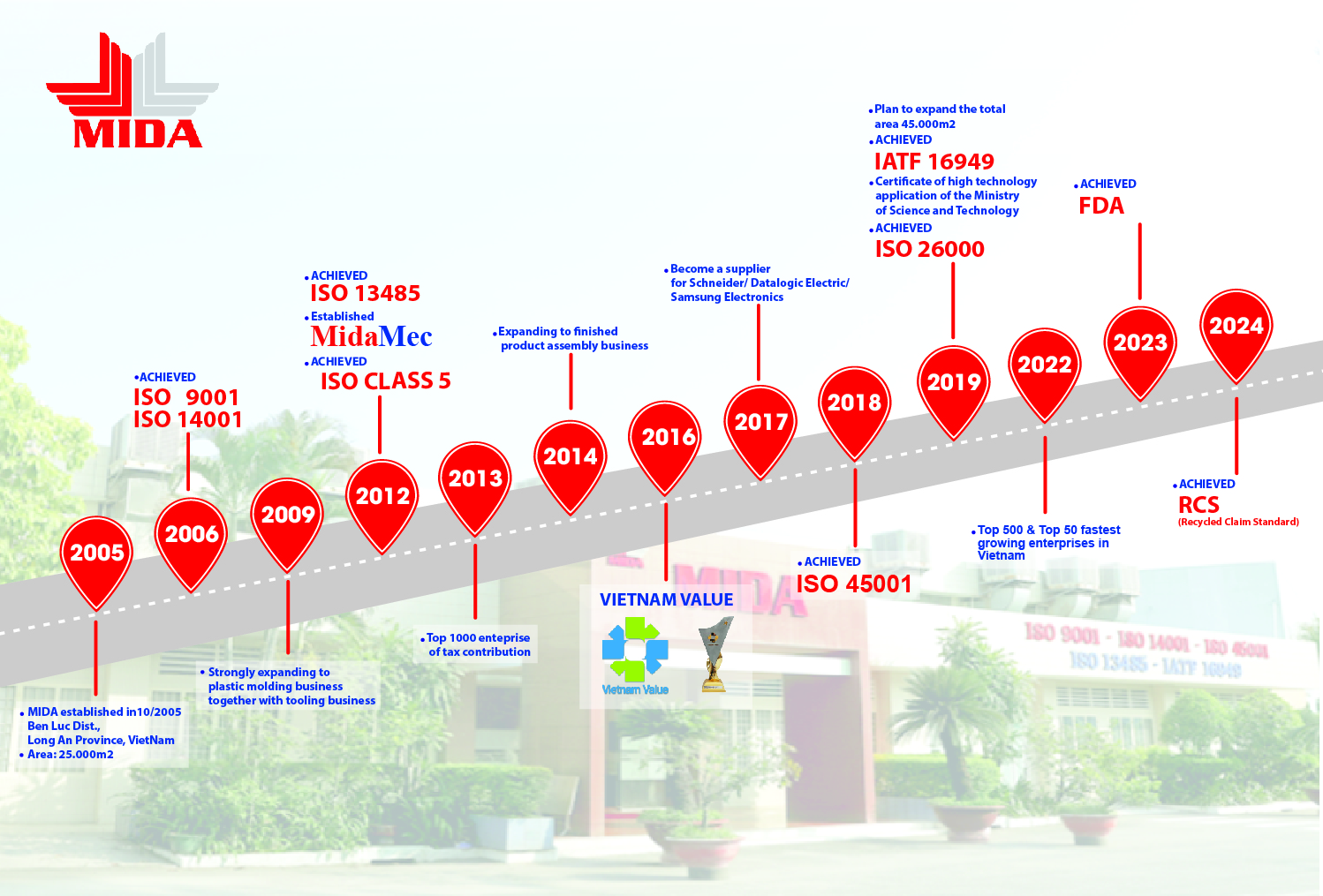

MIDA Introduction

MIDA - A leading manufacturer of precision injection molds and plastic components.

Established in 2005, based in Long An Province, Vietnam, with a factory scale of over 45,000m² and a system of workshops, modern machinery, and equipment utilizing technology from Japan, Switzerland, Germany, and America,...

MIDA provides comprehensive solutions, from design to complete finished product tailored to customer needs:

- Precision injection molds

- Engineering plastic components, medical plastics, auxiliary industries, and packaging for the spice industry

- Decoration and assembly of finished products as required.

With a team of leading experts in design, mold-making, and plastic product manufacturing,

MIDA's products are being exported to international markets including Japan, North America, Australia, New Zealand, and Europe. We serve multinational corporations such as Schneider Electric, Samsung Electronics, Datalogic, Amphenol, Furukawa, Eldor, and more

Equipped with the most precise 5-axis CNC machining machine from YASDA, a qualified Japanese brand, the machine offers accuracy to (04)four decimal places, equivalent to 0.1 micron.

In addition to CNC machining lines, MIDA has invested in a synchronized line of Charmilles machines, a Swiss brand known globally for its speed and precision in EDM machining.

With a wide range of plastic injection molding machines, with capacities from 15 tons to 850 tons, MIDA has the capability to meet most customer demands in the plastic injection molding industry.

Up until now, MIDA has produced and designed over 4,000 molds, ranging from simple to complex, achieving mold accuracy of 0.01 mm. These include cold runner, hot runner, 2-color molds, insert molds, and multi-cavity molds, all of which have been utilized in plastic injection production and exported worldwide

MIDA – A reliable and professional partner, committed to meeting all customer needs with the goal of becoming Asia's leading manufacturer of precision injection molds and plastic components.

Certifications and awards achieved

CONTACT FOR CONSULTANT

📧 Email: info@midamold.com

☎ Hotline: (+84) 926 60 8989

🌐 Website: www.midamold.com

🌐 Facebook: https://www.facebook.com/MIDAPRECISIONMOLD/

🌐 Youtube: https://www.youtube.com/@midamold7927

🌐 LinkedIn: https://www.linkedin.com/company/mida-precision-mold

🌐 Zalo: https://zalo.me/midaofficial

🌐 Instagram: https://www.instagram.com/midamold/

🌐 Tiktok: https://www.tiktok.com/@mida.mold

🌐 Twitter: https://x.com/mida_mold